The rapid advancement of Artificial Intelligence (AI) has ushered in an era of increasingly sophisticated robots capable of performing complex tasks across various industries. From manufacturing and logistics to healthcare and exploration, AI-powered robots are transforming the way we live and work. At the heart of these intelligent machines lie critical mechanical components, many of which are manufactured using Computer Numerical Control (CNC) precision machining. These meticulously crafted parts are not merely structural; they are fundamental to the accuracy, reliability, and overall performance of AI robots.

The integration of AI into robotics demands a level of precision that traditional manufacturing methods often struggle to achieve consistently. AI algorithms enable robots to perceive their environment, make decisions, and execute movements with remarkable accuracy. However, this intelligence is only as effective as the physical hardware that translates these digital commands into real-world actions. This is where CNC precision parts become indispensable.

Why CNC for AI Robot Key Components?

CNC machining offers several key advantages that make it the preferred method for producing critical components in AI robots:

Unparalleled Accuracy and Repeatability: CNC machines operate based on precise digital blueprints, ensuring that each part is manufactured to exacting tolerances. This level of accuracy is crucial for the intricate movements and delicate operations often required by AI robots, whether it’s a robotic arm performing surgery or a mobile robot navigating a complex warehouse environment. The repeatability of CNC processes guarantees that every replacement part will meet the original specifications, simplifying maintenance and ensuring consistent performance over time.

Complex Geometries and Intricate Designs: AI robot designs often incorporate complex shapes and intricate features to optimize functionality and efficiency. CNC machining can handle these complex geometries with ease, allowing engineers to design innovative and highly functional components that would be difficult or impossible to produce using traditional methods. This design freedom is vital for creating robots with advanced capabilities and a compact form factor.

High Material Versatility: AI robots utilize a wide range of materials depending on their specific application, including lightweight yet strong metals like aluminum and titanium, durable plastics, and specialized composites. CNC machines can process a diverse array of materials with precision, allowing manufacturers to select the optimal material for each component based on factors like strength, weight, wear resistance, and environmental compatibility.

Scalability and Efficiency: As the demand for AI robots continues to grow, efficient and scalable manufacturing processes are essential. CNC machining offers both. Once the initial programming is complete, CNC machines can produce large volumes of identical parts with consistent quality and minimal human intervention, leading to cost-effective and timely production.

Integration with CAD/CAM Software: The seamless integration of Computer-Aided Design (치사한 사람) and Computer-Aided Manufacturing (캠) software with CNC machines streamlines the entire production process, from initial design to final part. This digital workflow minimizes errors, reduces lead times, and allows for rapid prototyping and design iterations, accelerating the development cycle of advanced AI robots.

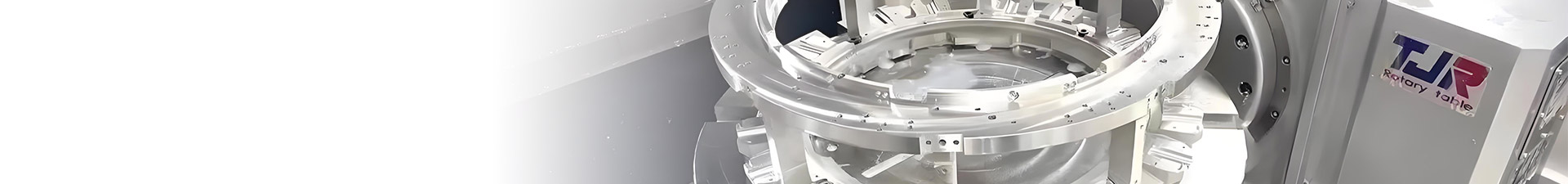

Key CNC Precision Parts in AI Robots:

The range of CNC-machined parts found in AI robots is extensive and varies depending on the robot’s specific function. Some common examples include:

Joints and Actuators: Precision gears, shafts, housings, and linkages that enable smooth and accurate movement of robotic arms and limbs.

End-Effectors and Grippers: Custom-designed tools and gripping mechanisms for manipulating objects with precision and dexterity.

Sensory System Components: Housings and mounting brackets for cameras, lidar sensors, and other environmental perception devices, ensuring accurate data acquisition.

Structural Frames and Chassis: Lightweight yet rigid frames that provide the necessary support and stability for the robot’s internal components and external interactions.

Drive System Components: Gears, sprockets, and motor housings that facilitate precise and reliable locomotion.

The Future of CNC in AI Robotics:

As AI robots become even more sophisticated and integrated into our daily lives, the demand for high-quality CNC precision parts will only increase. Ongoing advancements in CNC technology, such as multi-axis machining, automation, and the use of advanced materials, will further enhance the capabilities and performance of AI robots. The synergy between AI and CNC manufacturing is a powerful force driving innovation and shaping the future of robotics.

In conclusion, CNC precision parts are not just components; they are the foundational building blocks that enable the intelligence and capabilities of AI robots. Their accuracy, versatility, and scalability make them indispensable for creating the next generation of intelligent machines that will continue to revolutionize industries and transform our world.

CNC 5축 가공, 정밀 CNC 가공, 선반 가공, 터닝 & 밀링 가공, 밀링 5축 가공

CNC 5축 가공, 정밀 CNC 가공, 선반 가공, 터닝 & 밀링 가공, 밀링 5축 가공